- Home

- Media Kit

- Current Issue

- Past Issues

- Ad Specs-Submission

- Ad Print Settings

- Reprints (PDF)

- Photo Specifications (PDF)

- Contact Us

![]()

ONLINE

Growth with China’s Development

Editors’ Note

Xu Lejiang is an alternate member of 17th, 18th CPC Central Committee and a professor-level Senior Engineer. Xu joined Baosteel in 1982, rising from an engineer to a plant manager of blooming mill, and Assistant President of the group. He was appointed as Chairman of the group in January of 2007.

Company Brief

Baosteel Group Corporation (baosteel.com) is a typical enterprise arising from China’s reform and opening up. It was established in Shanghai in December of 1978 and has grown into one of the most competitive steel companies in China and the world. Year 2015 continued witnessing Baosteel on the Fortune Global 500 list for the 12th consecutive time and ranked 218th. In addition, Baosteel was also awarded the “Most Admired Chinese Company” for another year. By the end of 2014, Baosteel had more than 130,000 employees working all over the globe. Baosteel manufactures high value-added premium steel products with high technologies and fosters three major product categories, namely carbon steel, stainless steel, and special alloyed steel.

In LEADERS’ interview with then-Chairman of SASAC Li Rongrong in 2006, when Mr. Li talked about the reform and management of China’s state-owned enterprises, he said, “If every executive of China’s state-owned enterprises could be as excellent as those of Baosteel, the prospects of China’s state-owned enterprises would be very promising.” While learning about the history of Baosteel, we noted Baosteel’s significance as a landmark in the process of China’s reform and opening up. In 1978, right after Mr. Deng Xiaoping had returned from Japan, he determined to use the only foreign currency exchange (US$) that China had left to construct Baosteel.

Correct. During those hard years, a total of 12.8 billion RMB was invested into Baosteel’s first phase of the project. This means that every Chinese citizen had to donate 10 Yuan from their daily cost, suffering from hunger. Baosteel’s groundbreaking ceremony started in Shanghai on December 23, 1978, which was the very second day after the closure of China’s Third Plenary Session of the Eleventh Central Committee. As we all know, the turning point of China’s rise was marked by that meeting, which also defined China’s opening up and reform policy.

As a witness of Baosteel’s development, could you specifically talk about Baosteel’s significance to China’s reform and opening up?

In 1958, Chairman Mao brought up two key points regarding China’s development, i.e. “bread” and “steel.” Nobody can live without food and steel is the “bread” to all other industries as the most basic raw material to achieve industrialization. In 1978, China’s national steel output was less than 28 million tons, which severely suppressed China’s economic growth. On December 23, 1978, the construction of Baosteel marked the beginning of China’s opening up and reform. From the other way around, thanks to China’s opening up and reform policy, Baosteel could be established. We cannot imagine how different China would be today without this policy.

Baosteel has internationalization in its genes since the early days of China’s opening up. Due to the great vision of state leaders such as Deng Xiaoping and Chen Yun, Baosteel not only purchased the most advanced technology but established the best management methods. As Deng once said, China would be “fired” by the global community if our economy did not advance. The cost of over $100 million to import foreign technologies and their management showed Chinese leaders’ foresight and determination.

Nowadays, steel is utilized everywhere in people’s daily lives, in skyscrapers, high-speed rails, automobiles, airplanes, etc. Undoubtedly, people’s living has thus been substantially changed and improved. Currently in China, one of two cars on the road is made of Baosteel’s steel sheet. As the best steel company of China, Baosteel has contributed to China’s accomplishment over the past 30 years and greatly accelerated China’s opening up and reform. In fact, the establishment of Baosteel itself can be seen as one of the greatest achievements of the policy as well.

.png)

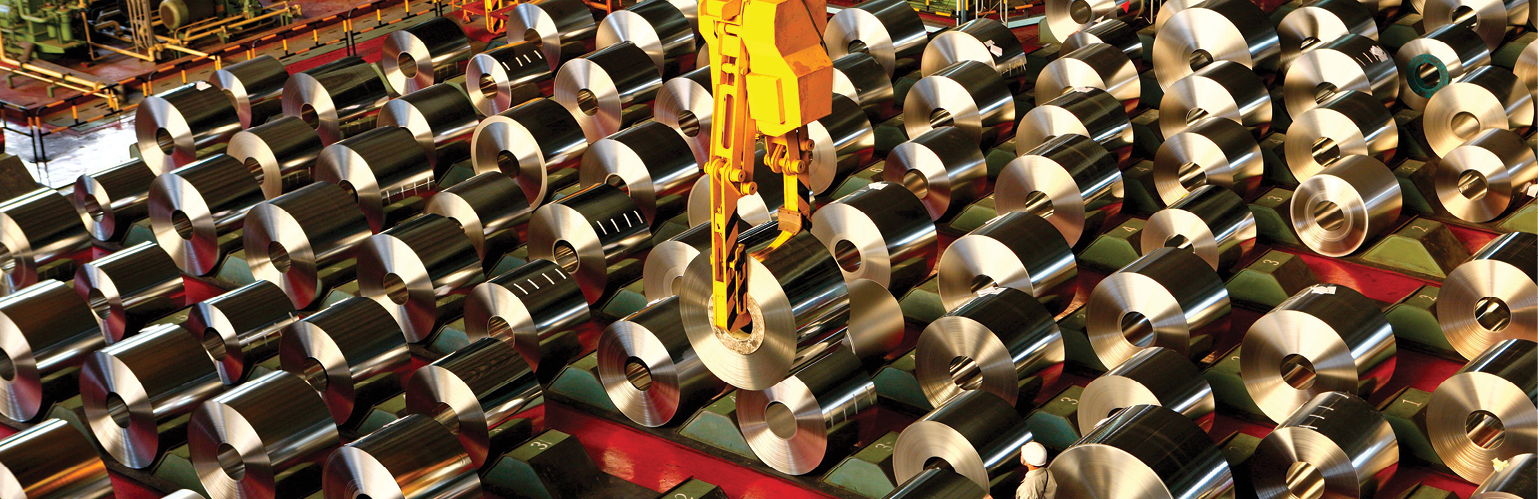

Baosteel factory

How did Baosteel not only excel within the industry domestically but also catch up with competitors worldwide?

I would give credit to a combination of various forces. First of all, China’s reform infused the DNA of opening up into Baosteel. Furthermore, the reform gave us opportunities to interact frequently with other countries, so we gained experience with the concept of a market economy. We realized that, in order to survive in a highly competitive environment, constant learning and innovation are vital. China’s opening up and reform policy had a profound impact on my generation; it paved a pathway for us to approach the world. Fortunately, we got the chance to observe the advanced management of some of the leading enterprises, and how their employees worked, which was, at first, astonishing to us. Compared with other enterprises in China, Baosteel had the advantage of an early start, without much historical burden or employee redundancy. As early as 1994, we already realized that finance is the core component of management and funding is the core component of finance.

I began my career in Baosteel as a small technician as soon as I graduated from college. By 1990, I was mainly focusing on production technique research. However, after I was transferred to headquarters, I realized that the expertise I lacked was in finance, accounting, and investing. In 1995, Baosteel offered me an opportunity to study abroad in Virginia, not far from Pittsburgh. I had spent most of that time studying all the financial statements of listed companies, such as the United States Steel Corporation. I analyzed the developing progress of the U.S. steel industry and observed its gradual adjustment. During the 1990s, I had devoted myself to studying the operation and management of every large steel company. Finally, I came to realize that Baosteel was not short of professional staff; instead, it fell on the transition from planned economy to market economy, and a more systematic operation flow.

Highlighting management and strategy, Baosteel had a different pathway of development from the beginning when we tried to avoid homogeneous competition. We positioned ourselves as producing “top quality goods.” At that time, China imported a lot of flat steel. When most Chinese enterprises started to produce this type of product, we changed our strategy to manufacture high-grade auto plates, which seized the best moment of the rapidly developing automobile industry in China.

Another reason that Baosteel can keep progressing is continuous innovation. Baosteel invests 2 percent of annual sales revenue into technology research and development each year, so newly developed products can be released on a regular basis, which gives us an outstanding advantage in market. In respect to the business model, Baosteel has redefined customer value and the true connotation of the steel industry. We have explored multiple usages of steel as a functional material, and try to transform our business model from solely manufacturing into providing service packages as well, with an attempt to change the role of the steel industry throughout the whole chain. As for management, our executives and staff worked together, learning from the most advanced counterparties to improve and reform our own management.

Baosteel Products"

The steel industry can be highly cyclical. After a round of high-speed development, it seems to have entered a trough. What’s your opinion about the current status of this industry?

It is true that China’s steel industry has had a long period of rapid development. The production of crude steel can take up 50 percent of the total all over the world. Now it has entered a mature stage. With a rising tide of impressive upgrades of our products, equipment, and techniques, Baosteel has accumulated comparative advantages to help it meet market demand. However, due to the current economic transition in China, the demand for steel has been depressed. Thus, the continual rise of the steel industry over the past 20 years showed signs of stopping, and the negative growth of crude steel consumption also appeared. Many problems began to come to light, like excess capacity. Currently in China, the utilization of the produced steel is less than 75 percent, which is lower than the worldwide average. Second, increasing stress from the perspective of environmental protection has discouraged steel production. This year, the Chinese government has issued the strictest environmental standards ever, which forces steel companies to either close down or invest heavily in environmental protection. The third factor is the transition from a low profit margin period to a complete financial loss period. In China, the market price of steel is equal to that of 20 years ago, but prices of the raw material, such as iron ore, are higher than they were 20 years ago, and the cost of labor is several times higher as well. These all account for the dilemma we are facing now.

Nevertheless, I remain confident about the future of the steel industry. In my opinion, China’s steel industry can be reborn during this painful phrase. There are several reasons for that.

First, we need to establish a better legal environment to let the competitive companies remain in business. The steel industry has a high consumption of energy. Enterprises qualified to survive must be able to control their pollution levels and be responsible for the sustainable development of society.

Second, the production distribution of China’s steel industry needs to be mapped out better. It has been 30 years since the beginning of China’s opening up and reform, but it is obviously unreasonable that the cities with a high consumption of steel, such as Guangdong, Guangxi, and Fujian, do not have large-scale steel factories nearby. It is very important to let the market run its own magic to select and leave the fittest in the market.

From past experience of the enterprises in developed areas such as Japan and Europe, the consumption of steel products will go down after reaching a peak. However, I don’t think that’s the same situation in China. Instead, we will reach a high point, go down slightly, stagnate, and go up again. Once we are able to grasp and fully understand this trend, we will deeply understand the words of Chairman Mao: “Anything worth achieving is not going to be easy.”

You have become the Chairman of Baosteel during good times. As a leader in the steel industry, what’s your strategy to make Baosteel survive during this tough time?

I became the Chairman of Baosteel in 2007. At that time, the annual profit of Baosteel was 35.6 billion RMB. I will remember the moment for my whole life: By the end of the third quarter of 2008, we had already made 34.5 billion RMB profit. We thought that we could set a new record in 2008, but the financial crisis hit us. During the last quarter of 2008, 12 billion RMB of profit was gone, which meant that more than one hundred million RMB was lost per day. From then on, the steel industry has entered a downturn. However, we are treating this depression as a time to transform and reshuffle. More specifically, we are planning to perform three types of transition.

First, we will transform steel to a more versatile material. As a traditional metal, steel has irreplaceable advantages, but today, its limitation has arisen. As a result, exploring more environmentally friendly, economic, and productive metal material is one of the priorities of Baosteel. For example, 80 percent of the material used by nuclear power units is nickel, and the other 20 percent is chromium, molybdenum, and iron. They do not use traditional steel any longer, so we have to cater to the needs of customers and develop products to meet this new orientation.

Second, we will transform from production to service. We will begin to make profits through more value-added services. We want the manufacturing to become just a part of our industry chain, and we are revolutionizing traditional production towards both ends of the “smiling curve,” which is the service. Other than technique innovation, the innovation of the business model is actually more important. In the steel industry, the old pattern was that the sale of steel would go down with the decrease of infrastructure construction. However, we are in the Internet era, which has significantly solved information asymmetry problems. This provides opportunities for the steel industry in many respects, and can create more value for society as a whole. I realized that Baosteel could achieve the transition and adjustment of industrial structure with the help of the Internet. For instance, the “Ouyeel” we launched this year is a third-party service platform that effectively integrates the services of business, finance, and storage including a comprehensive supply chain of services and forming a thorough service system through market segmentation.

The third is to expand from China to the world. Baosteel should take better advantage of the “Belt and Road Initiative” strategy, so that we can utilize global resources to optimize the pattern and capacity of supply chain, enhance our service, and drive China’s development further ahead.•